Managing Power Density in Compact Electronic Designs

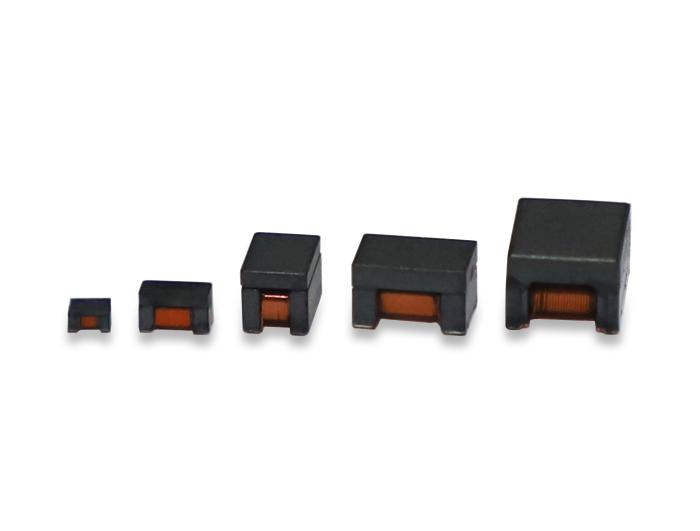

Modern electronic systems face a constant push for higher performance in smaller packages. This creates a significant challenge for power management, where space is limited but efficiency demands are high. The core of this challenge often lies in the selection of passive components, particularly the chip power inductor. As a fundamental element in switching power supplies, the right chip power inductor directly influences overall system efficiency, thermal performance, and physical footprint. We at Mentech focus on engineering magnetic components that meet these concurrent demands for miniaturization and electrical performance.

Overcoming Thermal and Space Constraints

A primary issue in dense circuit layouts is heat management. An inefficient chip power inductor can become a major source of power loss, leading to elevated operating temperatures that jeopardize surrounding components. The design of our chip power inductor products prioritizes low DC resistance and advanced core materials that minimize energy loss as heat. This allows designers to maintain high efficiency without resorting to larger, bulkier components for thermal reasons, thereby preserving valuable board space in applications from compact communication devices to automotive control units.

Ensuring Stable Performance under Electrical Stress

Beyond mere size, a chip power inductor must maintain its electrical characteristics under real-world operating conditions. A key failure point is saturation, where the inductor cannot store more magnetic energy, causing a catastrophic drop in inductance. Our components are engineered with a high saturation current rating, ensuring they continue to perform effectively under high load conditions and current spikes. This robustness is non-negotiable for the reliability of power supplies, where consistency directly impacts the functionality of the entire system.

Facilitating Efficient and Reliable Manufacturing

The component selection process extends beyond electrical specs to manufacturing viability. The surface-mount nature of a modern chip power inductor is critical for automated, high-volume production. Its compact and robust package ensures it can withstand the reflow soldering process and maintain a secure connection to the PCB. This reliability streamlines assembly, reduces manufacturing defects, and contributes to the long-term durability of the final product, which is a critical consideration for our clients in various global markets.

Chip Power Inductor vs. RF Transformer

It is important to distinguish the role of a power management component from a signal integrity component.

A Chip Power Inductor is primarily used for energy storage and filtering in power conversion circuits (like DC-DC converters). Its design is optimized for high efficiency in managing power, with a focus on high current handling, low losses, and preventing saturation.

An RF Transformer is specialized for signal processing in high-frequency applications. It operates over a wide band (e.g., 0.1 to 6000 MHz) and is designed for tasks like impedance matching and isolation to ensure clear signal transmission, not for storing large amounts of energy.

The choice is defined by the application's primary need: stable power delivery versus high-frequency signal coupling.

Successfully navigating the challenges of power density requires a strategic approach to component selection. The chip power inductor is more than a simple part; it is a key determinant of a design's efficiency, size, and thermal performance. At Mentech, we combine years of expertise with advanced manufacturing capabilities to produce high-quality magnetic components, including a comprehensive range of chip power inductor solutions. We are dedicated to providing reliable, excellent-quality products that address the specific challenges faced by designers. For power components that help you overcome the constraints of modern electronics, contact Mentech to discuss your application requirements.