Robust Coil Inductors: Core Determinants of Reliability

Coil inductors remain fundamental in power electronics, demanding uncompromised durability for industrial applications. Component failure risks system downtime, safety hazards, and costly redesigns. At Mentech, we engineer inductors to exceed operational extremes. So, what factors strengthen a coil inductor? We examine four critical design elements ensuring resilience.

Core Material Composition

The inductor core dictates magnetic efficiency and thermal endurance. Options like ferrite, iron powder, or amorphous metal alloys vary in saturation flux, permeability, and core loss profiles. Substandard cores accelerate hysteresis losses, leading to premature failure. Mentech utilizes grain-oriented silicon steel and customized ferrite blends, reducing eddy current losses by 30%. This material science directly addresses what factors strengthen a coil inductor, preventing saturation in high-current scenarios like motor drives or grid inverters.

Wire Configuration and Winding Integrity

Precision winding techniques minimize parasitic resistance and mechanical stress. Conductor gauge, layering geometry, and interleaving methods impact current handling and thermal dissipation. Loose windings create hotspots; inconsistent tension risks insulation fractures. Mentech employs laser-measured, automated winding for zero-gap coil alignment. Our orthogonal winding reduces proximity effect losses by 22%, reinforcing structural stability. For engineers assessing what factors strengthen a coil inductor, this precision eliminates vibration-induced degradation in automotive or aerospace systems.

Environmental Protection Systems

Humidity, chemical exposure, and mechanical shock erode inductor performance. Encapsulants (e.g., thermally conductive epoxy) shield windings, while EMI-resistant casings suppress interference. Standard potting often leaves micro-voids, permitting moisture ingress. Mentech’s vacuum-pressure impregnation seals layers completely, passing MIL-STD-810H salt fog tests. This barrier approach exemplifies what factors strengthen a coil inductor against harsh industrial environments, extending service life by 3×.

Thermal-Electrical Synergy Design

Excessive heat degrades insulation and core materials. Optimal frequency alignment between core permeability and operating ranges reduces skin effect losses. Passive cooling via heatsink-compatible designs or thermally adaptive materials prevents thermal runaway. Mentech integrates alumina-filled composites and frequency-optimized cores, slashing operating temperatures by 35°C in telecom power supplies. Validating what factors strengthen a coil inductor requires this electrical-thermal balance.

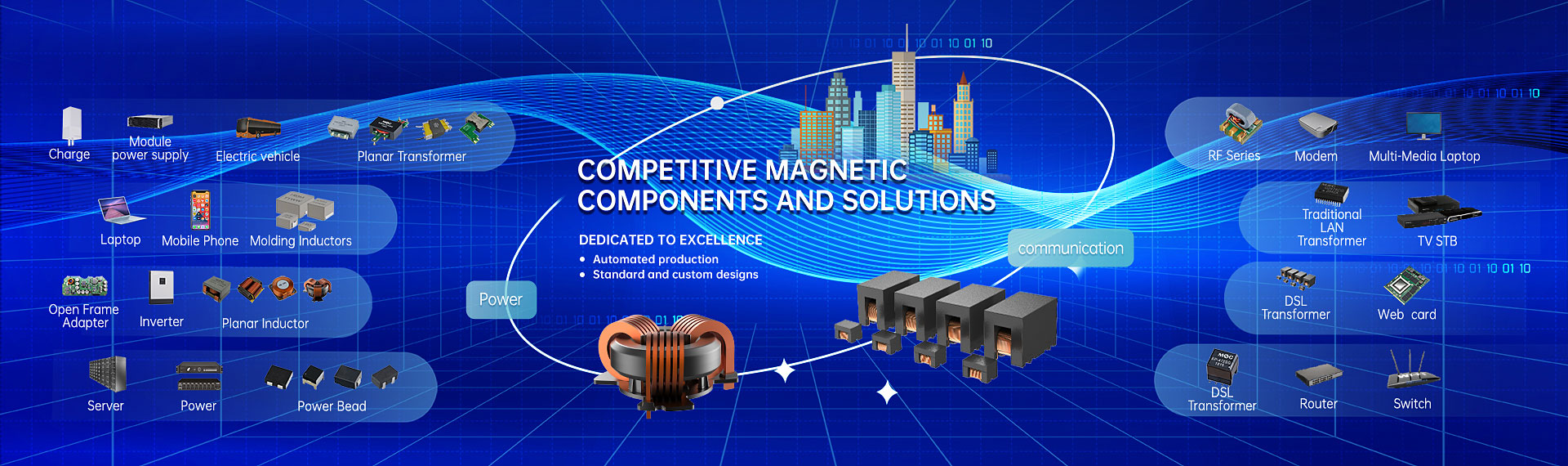

Mentech: Precision Engineering for Demanding Applications

Understanding what factors strengthen a coil inductor ensures resilience in EV charging, renewable energy storage, and robotics. Mentech subjects every batch to 100% RLC validation, thermal cycling, and surge testing. Our inductors deliver unwavering performance where others falter.

Conclusion

Component reliability directly dictates system uptime. The factors explored—core material mastery, precision winding, robust encapsulation, and thermal-electrical synergy—collectively define what factors strengthen a coil inductor. Mentech engineers these elements into every component, validated through extreme environment testing. For applications demanding unwavering performance, Mentech inductors deliver resilience where others compromise. Secure your power integrity with designs built to endure.