Meeting Automotive Electrification’s Toughest Transformer Demands

Engineering Resilience: Core Technical Advantages

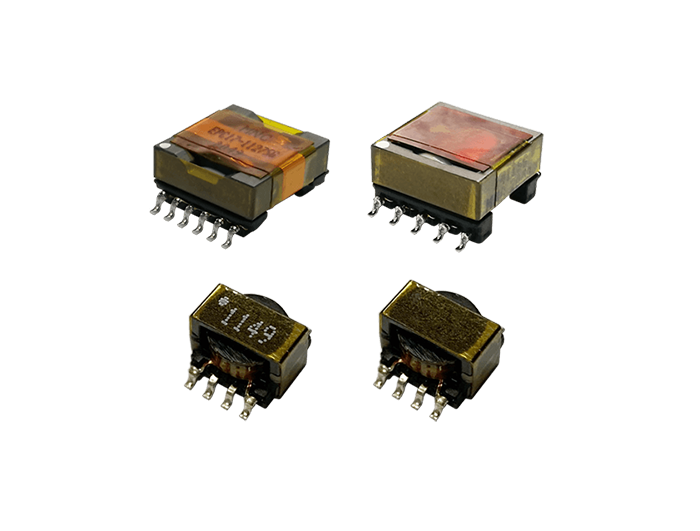

Mentech’s automotive transformers deliver mission-critical stability through proprietary design. We achieve high insulation strength (>4kV) to prevent dielectric breakdown in high-voltage battery systems, coupled with ultra-low electromagnetic losses (<3% at full load) to maximize efficiency. Critically, minimized distributed capacitance (<10pF typ.) eliminates high-frequency noise interference in sensitive control circuits. These parameters, rigorously validated across our extended temperature range, make Mentech the preferred automotive transformer partner for next-generation powertrains where safety margins cannot be compromised.

Mission-Critical Applications: Powering Electrified Systems

Our transformers enable breakthrough performance across electrified vehicle platforms. In Battery Management Systems (BMS) for EVs and hybrids, they ensure precise cell voltage monitoring and balancing. Motor control units leverage their noise-immune design for accurate traction inverter switching, while DC-DC converters utilize their high-efficiency (>97%) power transfer for stable voltage transformation. Further, Mentech’s automotive transformers safeguard battery power control networks through inherent short-circuit protection – making them indispensable for ASIL-C/D rated systems.

Quality Beyond Certification: Mentech’s Automotive DNA

Compliance is our baseline – excellence is our standard. Every Mentech automotive transformer undergoes 25+ validation tests exceeding AEC-Q200 requirements, including 1,000-hour thermal aging simulations and mechanical shock/vibration profiling. Our IATF 16949-certified facilities implement statistical process control (SPC) for CpK>1.67 critical dimensions, while in-house material labs validate magnetic core performance under -40°C cold starts. This ecosystem ensures defect rates below 10ppm – transforming risk into reliability for safety-critical applications.

Supply Chain Certainty for Global Vehicle Platforms

Mentech delivers automotive-grade resilience beyond engineering. Strategically located manufacturing hubs in Vietnam (duty-free EU/NA access), Dongguan (R&D center), and Jiangxi guarantee:

Regional Buffer Stocks: 8-week inventory for urgent BMS prototype demands

Scalable Capacity: Dedicated EV production lines for 500k+/month volumes

Full Traceability: Material genealogy from raw ferrite cores to serialized transformers

This infrastructure eliminates supply chain disruptions – a key reason 8 Top 10 global EV suppliers partner with Mentech.

Conclusion

The reliability of transformers is being more and more appreciated as the power demands of automobiles increase. Precision magnetics, an area where Mentech has excelled for 15 years, allows them to fill gaps left by more traditional parts. In order to help you achieve functional safety goals, reduce footprints, and push voltage boundaries, our automotive transformers combine electromagnetic superiority with durability that has been demonstrated on the battlefield. Transform tomorrow's mobility by partnering with Mentech.