Powering Precision: Mentech’s Engineered Molded Inductors Solve Modern Electronics Challenges

In an era where electronic devices demand unparalleled power efficiency, electromagnetic silence, and unwavering reliability under stress, component selection defines success. Mentech addresses these critical needs head-on with our advanced molded inductor technology. Designed for engineers confronting EMI interference, space constraints, and thermal extremes, our solutions deliver robust performance across automotive, medical, industrial, and consumer applications. Discover how Mentech’s innovation transforms power integrity.

Superior Performance Through Advanced Magnetic Shielding

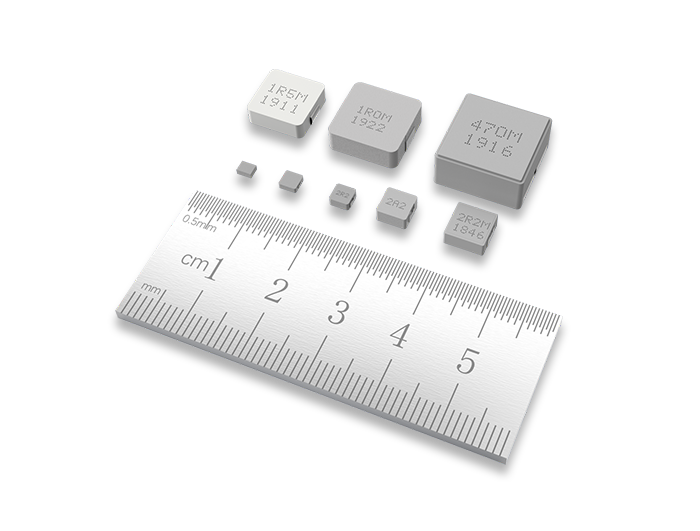

The core architecture of Mentech’s molded inductor features a closed magnetic circuit, fundamentally eliminating electromagnetic interference (EMI) and reducing buzzing noise to near-imperceptible levels. This shielding is non-negotiable in sensitive environments like medical diagnostics or vehicle control systems. Beyond noise suppression, our design maintains exceptionally high current handling under sustained high-frequency operation and elevated temperatures—preventing saturation that compromises performance. The compact form factor integrates low DC resistance with mechanical ruggedness, enabling reliable operation in vibration-prone or space-constrained applications. Crucially, Mentech molded inductors meet AEC-Q200 automotive-grade standards, guaranteeing resilience where failure is not an option.

Enabling Breakthroughs Across Critical Sectors

Mentech molded inductors serve as the silent backbone of innovation in multiple high-stakes industries. In automotive electrification, they optimize DC-DC converters within EV powertrains and high-efficiency LED lighting systems, ensuring stable voltage delivery. For portable electronics—from laptops to life-dependent medical wearables—these components maximize battery longevity while minimizing acoustic noise in ultra-compact designs. Medical imaging equipment and micro-devices like insulin pumps rely on their EMI-free operation for patient safety and signal accuracy. Industrial automation systems leverage their durability to maintain precision control in harsh manufacturing environments with extreme temperatures or electrical noise.

Mentech: Where Precision Engineering Meets Trusted Quality

For over a decade, Mentech has pioneered magnetic solutions through rigorous science and uncompromising validation. Our ISO-certified production facilities utilize fully automated manufacturing and AI-driven optical inspection, ensuring microscopic consistency in every molded inductor. Each unit undergoes 100% electrical testing against AEC-Q200 protocols before release. Collaboration with Mentech unlocks tailored specifications, rapid prototyping with 72-hour sample turnaround, and global engineering support. Our commitment extends beyond performance—we adhere to RoHS/REACH environmental standards, aligning advanced technology with sustainable responsibility.

Conclusion

As electronics evolve toward higher power densities and miniaturization, the molded inductor’s role becomes increasingly strategic. Mentech’s ongoing R&D focuses on pushing efficiency boundaries while maintaining ultra-low acoustics and thermal resilience. Whether enabling next-gen EV battery systems, silent medical implants, or rugged Industry 4.0 robotics, our components ensure systems operate at peak potential—cooler, quieter, and longer-lasting.

Ready to overcome your power design constraints? Contact Mentech today for datasheets, samples, or a technical consultation with our engineering team.